- +90 212 667 62 56

- Bolts, Rivets and Special Fasteners

Although the connection of structural elements falls within the field of civil engineering, I cannot pass without pointing out some very important points here.

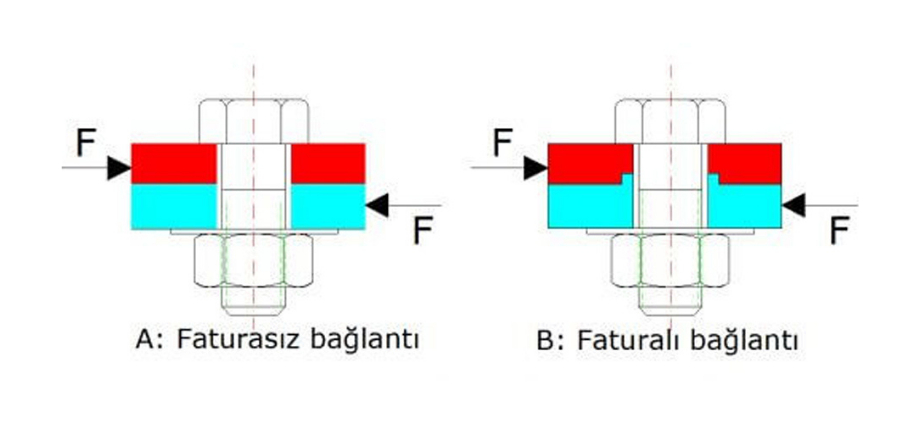

Axial and shear forces can be met by using high-strength and corrosion-resistant pre-stressed bolts for connecting the structural elements. Because the friction force provided by the pressure created by the tension in the axial direction on the connected surfaces is sufficient for a proper connection by preventing the elements from sliding in the shear direction.

Prestressed bolts can provide 40 to 55% more secure fastening than hot rivets, which were used before, in the fastening of structural elements. It is essential to use high pre-stressed bolts in structural elements where force directions may change and may be exposed to impact and vibration.

It is ensured that the loosening that may occur due to heat or corrosion in the elements connected with pre-stressed bolts is prevented. To prevent loosening in such places, the pre-stressed bolts must be stretched to the yield limit. If the pre-stressed bolts are not tightened to the yield limit, loosening will be inevitable in a short time. The yield limits of the bolts are found in the tables available from the bolt supplier.

Another issue that will prevent the bolts used in steel structures from loosening is tightening the bolts using suitable tightening tools. The tightening torque value is uncertain when tightening with air impact guns. Guns with adjustable tightening torque must be used in bolt connections of steel structures.

Other issues that will prevent loosening are that the connection surfaces are clean, not rusty, free of welding or cutting burrs, oil-free and dry. If necessary, sandblasting should be done on very dirty, rusty, rough surfaces. Other important issues regarding the surfaces to be bonded are that the surfaces must be unpainted and not galvanized.

If there is more than one bolt in the same row in structural steels, the middle ones are tightened first, and the ones on the sides are tightened last. In the first round, 60% of the spin value is applied, in the last round, 100% of the spin value is completed.